One of the most common uses of alpha alumina submicron

Alpha alumina submicron

The alpha alumina submicron is milled and carefully classified to reduce the potential for crystal aggregation. Alpha alumina submicron is applied to textile and polish components, and its other uses are in the field of pharmaceuticals and cosmetics.

General characteristics of alpha alumina submicron

Among the general properties of alpha alumina submicron are the following:

- Rapid chemical immobilization

- Dielectric properties

- Its hardness is high.

- Its compression strength is high.

- Wear and good resistance to wear

- It has a high degree of resistance

- It has excellent insulation properties.

- Has a good resistance to heat shock.

- It has a high melting point.

Sample alpha alumina submicron applications

Alumina submicron is used in a number of ways, including:

- Polished and polished

- Construction of ceramic structure

- Ceramic technical construction

- Making armor

- Manufacture of vehicles

- Pharmaceutical Applications

- Manufacture of Veneers

- Filler in therapeutic, cosmetic and pharmaceutical

One of the most common uses of alpha alumina submicron

One of the most important and common applications of alpha alumina submicron is the construction of transparent and strong ceramics used in dental restorations. It is an ideal ceramic restorative material that should have excellent aesthetic and mechanical properties. Our hypothesis is that high transparency and robustness of polycrystalline ceramics is achieved through microstructural planning. The aim is to show the superior optical and mechanical properties of a new class of submicron sized alumina ceramics compared to today’s modern dental ceramics.

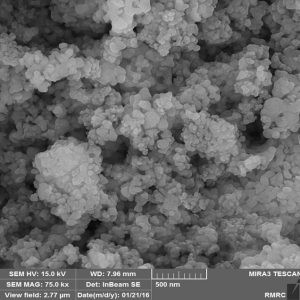

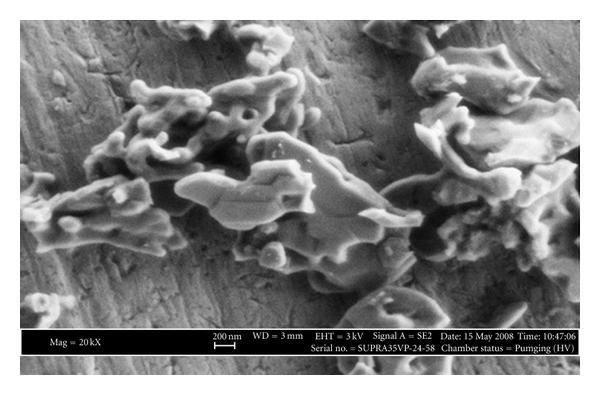

Figure2- alpha alumina submicron

One of the most important applications of alumina submicron is the use in the construction of transparent and strong ceramics for tooth restoration. The predictions fit well with the measured values. Transparency parameter and contrast ratio of developed and new alumina were measured with different spectra in black and white background. The bending strength of alumina was determined by bending test. The findings show that for the manufacture of polycrystalline alumina ceramics, the grain size must be <1 μm with a porosity value of <0.7% which can have high commercial transparency. These values are higher than the transparency of lithium, ceramic and zirconia, including the most transparent cubic zircon. The strength of these sub liquid granular aluminum is significantly higher than that of cubic zirconia.

medicine online shopping

I am not sure where you are getting your information,

however good topic. I needs to spend some time finding

out much more or figuring out more. Thank you for excellent information I was on the lookout

for this info for my mission.