What is alpha alumina submicron?

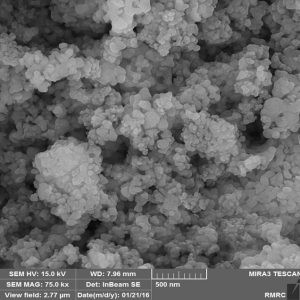

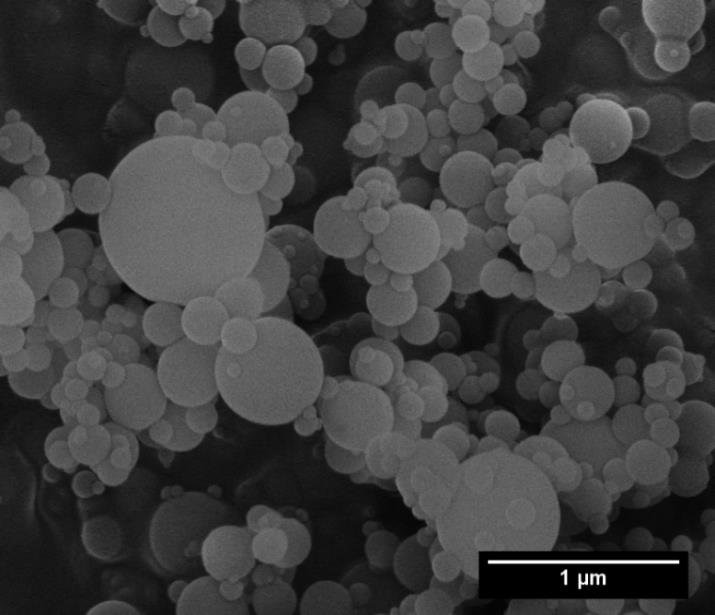

Alpha alumina submicron fabrication is associated with the preparation of anhydrous food. In fact, its construction is related to a process for producing alumina powder without the need for heavy mechanical grinding. Alumina is generally one of the pure chemical ceramic powders. This powder is as commercially available as submicron particles. High purity and uniform alumina powders with a small particle size of less than about one micron are among these materials.

Alpha alumina submicron preparation process

Submicron particles are used in the alpha alumina submicron production process. This submicron comprises the calculation of hydrocarbon alumina with an area of about 3 to about 90 square meters per gram to produce anhydrous alumina. When agglomerated, it forms an anhydrous alumina powder having a medium particle. Its size is less than one micron. Hydrated alumina is obtained by mixing water and a precursor to aqueous alumina such as boehmite. This is done at temperatures above 250 degrees Fahrenheit.

Application of alpha alumina submicron

In many applications of alpha alumina submicron, high purity, small size and uniformity of water free particles in alumina powders are required. For example, in the production of high tech ceramics, it has been found that the use of alpha alumina submicron with small, uniform particle sizes makes the product less susceptible to fracture and other breakdowns.

What is alpha alumina submicron?

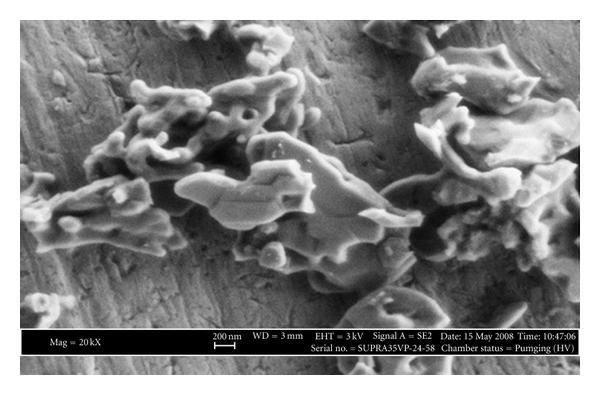

Currently known technology for the production of small and uniform particle size alpha alumina powders involves hydrated alumina firing. These include alumina trihydrates or monohydrates. They require high temperatures to convert hydrated alumina to alpha phase. Small crystals of alpha alumina submicron precursors are formed in larger particles. They melt in clusters of alumina crystals. To achieve the size of the alumina submicron, highly agglomerated alumina particles must be compressed into mechanical grinding. Ball mill is expensive and expensive. And the resulting product is rarely as uniform as the alumina powder particles. Compact grinding always introduces impurities into the final alpha alumina powder. Due to the use of powder in ceramic products manufactured. These impurities of a uniform size of alumina particles show weaknesses in the mechanical equipment for the production of ceramic products. One goal of the invention of alpha alumina is to provide an optimal process for the production of water free alumina of uniform particle size.