Production of alpha alumina nano powder

Production of alpha alumina nano powder

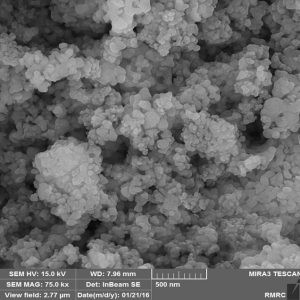

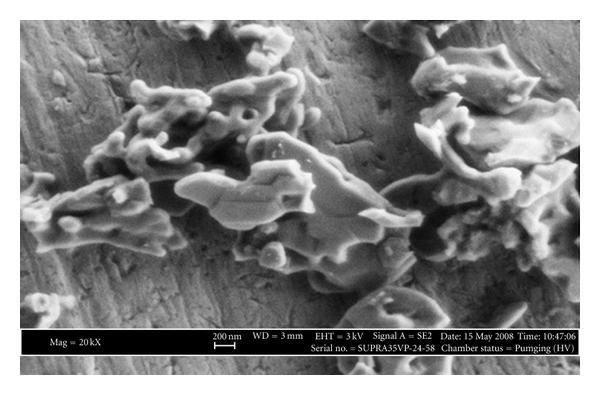

Here, we have attempted to investigate the effect of composition time on the synthesis of alpha alumina nano particles. Alumina nanoparticles are first synthesized by alkoxide conduction using sol gel method. Aqueous solutions of aluminum isopropoxide and aluminum nitrate Nano hydrate are then used to prepare alumina sol. Sodium silicon gasoline sulfonate is used as a surfactant stabilizing agent. The solution was stirred at 60 ° C at different times of one day, two days, three days and four days. The samples are then characterized by X-rays, calorimetry analysis, differential calorie scanning, transmission electron microscopy and scanning electron microscopy. Introducing different composition times affects the particle size and shape and the rate of aggregation. As the mixing and mixing time increases, the particle size decreases with the passage of one day and two days. The mixing material becomes harder to mix for two to three days, equivalent to 60 hours. The best particle size obtained after two days of stirring is -20 nm.

Production methods of alpha alumina nano

Alpha alumina nano is one of the most widely used materials in ceramic manufacturing. It is used as a catalyst, a catalyst support and an adsorbent. It has a wear resistant coating. This material can be prepared by any of the following methods:

- Sol gel

- Hydrothermal water

-

Duplicate

Mechanical milling

- The vapor phase reaction

- Methods of combustion

It is a little difficult to obtain alpha alumina nano powder. This is difficult for two reasons. First, the alumina nanoparticle powder is stabilized after being operated at high temperatures. This will easily stimulate grain growth but make it difficult to obtain nano particles. Second, the alumina nano particles are collected in the dehydration process using the humidity method. Therefore, it is necessary to find a new way to solve this problem. Gel synthesis is a relatively inexpensive method. On this day, the oxide material is mixed with good control over the stoichiometry and morphology. Atomic scale materials are suitable for particular applications.