-

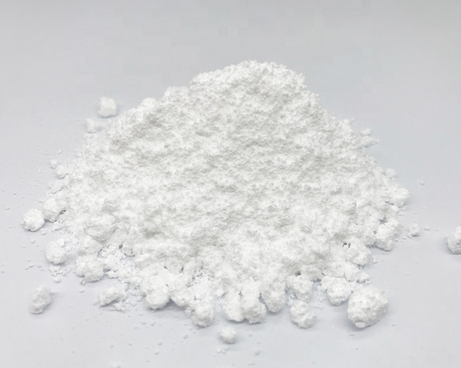

One of the most common uses of alpha alumina submicron

Alpha alumina submicron The alpha alumina submicron is milled and carefully classified to reduce the potential for crystal aggregation. Alpha alumina submicron is applied to textile and polish compone...

2020-08-11 -

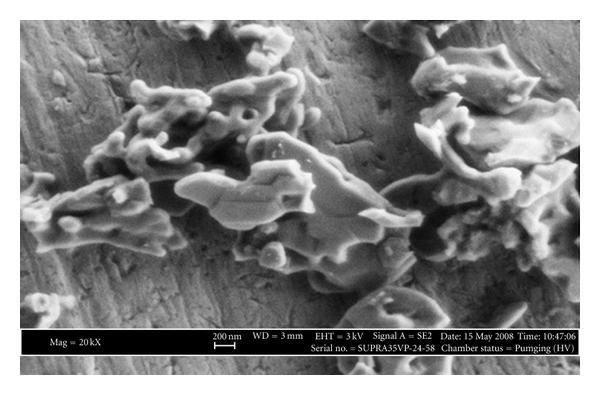

Applications of zirconia stabilize yttria

Zirconia stabilize yttria Zirconia stabilize yttria is a ceramic material in which the cubic crystalline structure of zirconium dioxide is stabilized by adding yttria oxide at room temperature. Typica...

2020-07-25 -

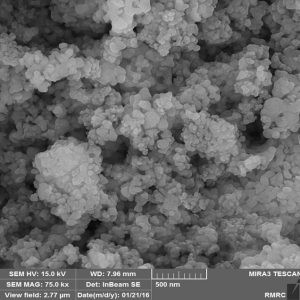

Production of alpha alumina nano powder

Production of alpha alumina nano powder Here, we have attempted to investigate the effect of composition time on the synthesis of alpha alumina nano particles. Alumina nanoparticles are first synthesi...

2020-07-16 -

The effect of alpha alumina nano on improving the quality of concrete

Alpha alumina nano Alpha alumina nano is one of the most commonly used materials in ceramic and building materials including concrete. Alumina is the most widely used oxide ceramic in various industri...

2020-03-21 -

Zirconia stabilize yttria in ceramics

Zirconia stabilize yttria in ceramics As you know, stabilize zirconia yttria is a material used in ceramic and dental construction. The most common form of zirconia stabilized in is zirconia stabilize...

2020-02-09 -

?What is Zirconia stabilize yttria

What is zirconia stabilize yttria? Zirconia stabilize yttria is a zirconium oxide based ceramic type. Such a material has a specific crystalline structure of zirconium oxide. By adding ether oxide to ...

2020-02-08 -

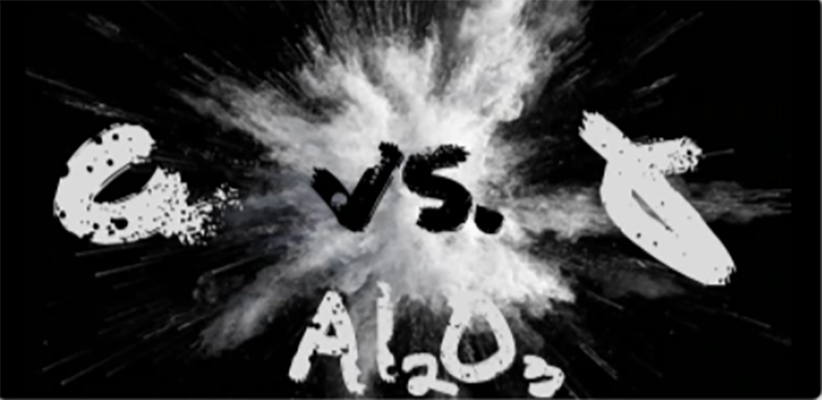

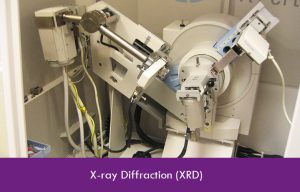

Differences between Alpha and Gamma Aluminum Oxide Nanoparticles

Differences between Alpha and Gamma Aluminum Oxide Nanoparticles Structural difference: in terms of structure, the alpha-alumina is trigonally structured (R-3c) with an ABAB arrangement of planes of ...

2020-02-06 -

What is alpha alumina submicron?

Alpha alumina submicron fabrication is associated with the preparation of anhydrous food. In fact, its construction is related to a process for producing alumina powder without the need for heavy mech...

2020-02-04 -

What is alpha aluminum nano?

What is alpha aluminum nano? Aluminum oxide or alumina is an important amphoteric oxide of inorganic compounds and is known by various brands such as alumina and corundum. The major use of aluminum ox...

2020-02-02 -

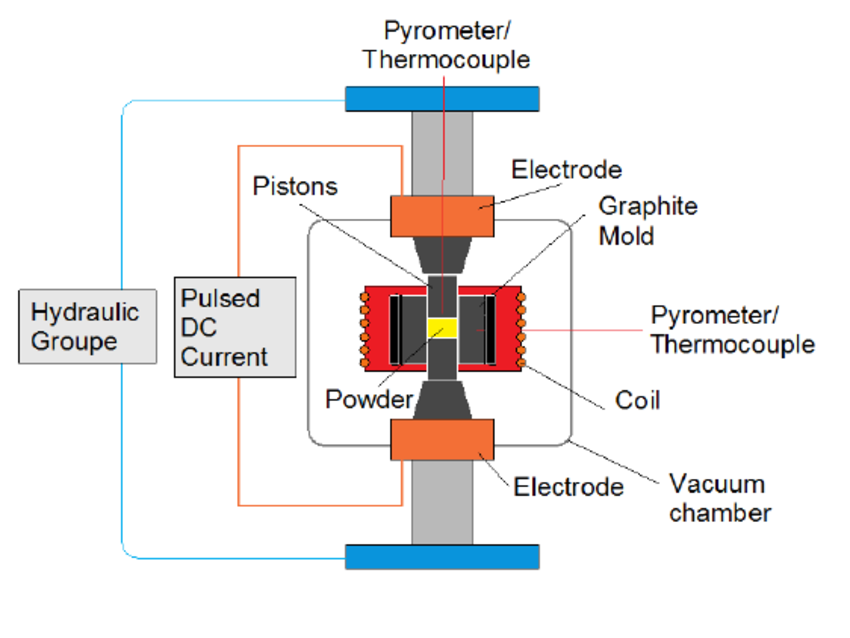

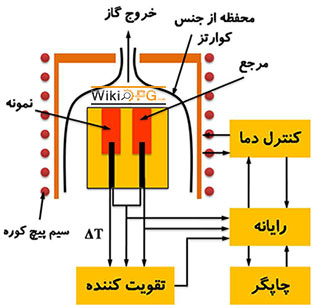

Plasma Spark Sintering; A new Sintering Method

The plasma spark sintering method is one of the newest methods of producing and forming powder. This method is used to make ceramic or metal parts from the powder of those compounds. The samples obtai...

2019-10-23