Al2O3 powder (Alumina)

Aluminum oxide exists in several different crystallographic forms, of which corundum is most common. Corundum is characterized by a high specific gravity (4.0), a high melting point (about 2,050 °C, or 3,700 °F), great insolubility, and hardness.

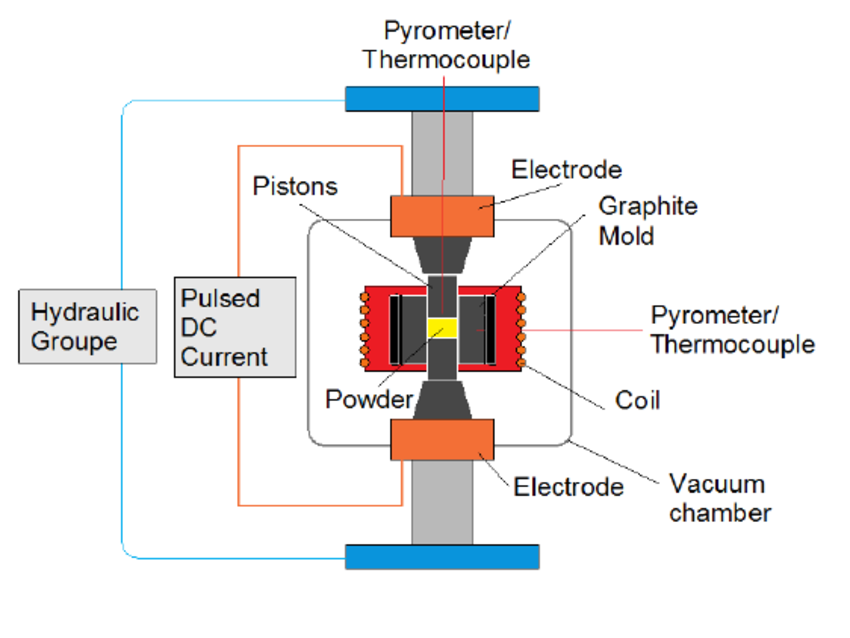

Processing of Alumina

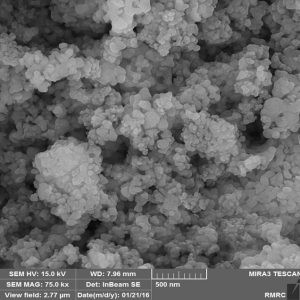

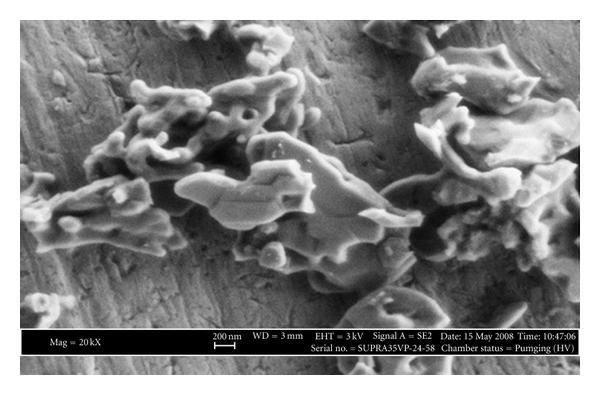

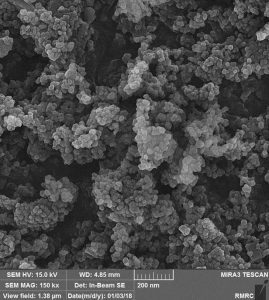

The alumina transformation temperature is theoretically 1200 ° C, while experimentally this temperature is close to 1400 ° C. The critical growth temperature of alumina grains is 1000 ° C, so at high temperatures as high as 1400 ° C one cannot expect to produce alumina with low grain size (1 to 5 microns) directly and typically by conventional methods. Mechanical mills are used for this. By mixing Alumina based nano material our company (RASA) invented, we were able to reduce the alumina calcination temperature to 1050 ° C. This results in the production of low grain size alpha aluminum being directly produced directly and requires no intermediate process such as de-agglomeration and mechanical milling, thus reducing production costs.

For the production of alumina 100% single phase for nearly 1 year research and development work. The major challenge of producing this material at high temperature of transformation is also the stability of the pre-alumina intermediate phases. Raika Sanat Afrand(RASA) Co., with the invention of an additive, succeeded in producing this product at a lower temperature.

Competitive advantages of our product:

- 100% phase purity (single phase alpha alumina)

- 5% chemical purity

- Competitive price

- Production in different phase purities and sizes(1-5, 10,20, 40-50, 70, 100 micro meter) according to customer demand(Both alpha and gamma aluminum and together composition)

- Simple production technology and low cost production

- Ability to increase production at large scale