Zirconia stabilize yttria in ceramics

Zirconia stabilize yttria in ceramics

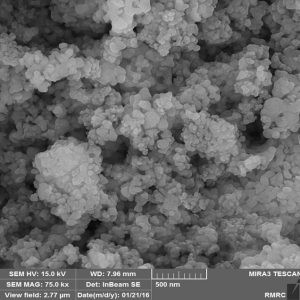

As you know, stabilize zirconia yttria is a material used in ceramic and dental construction. The most common form of zirconia stabilized in is zirconia stabilize yttria ceramics. The usual composition of zirconia stabilized is as follows:

- Yttria 94.7% ZrO2 + 5.2% Y2O3

- ZrO2 97% + 3% Y2O3 or mole

Different of alumina and zirconia stabilize yttria

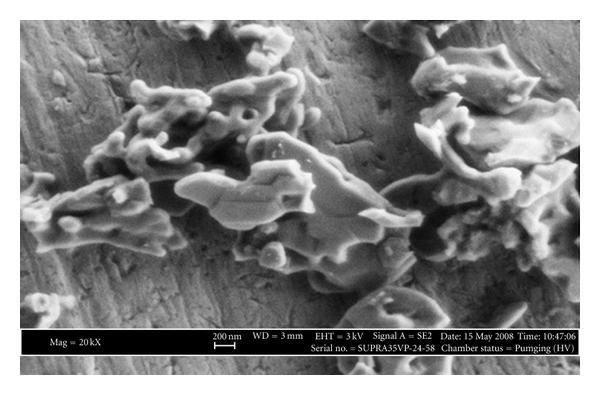

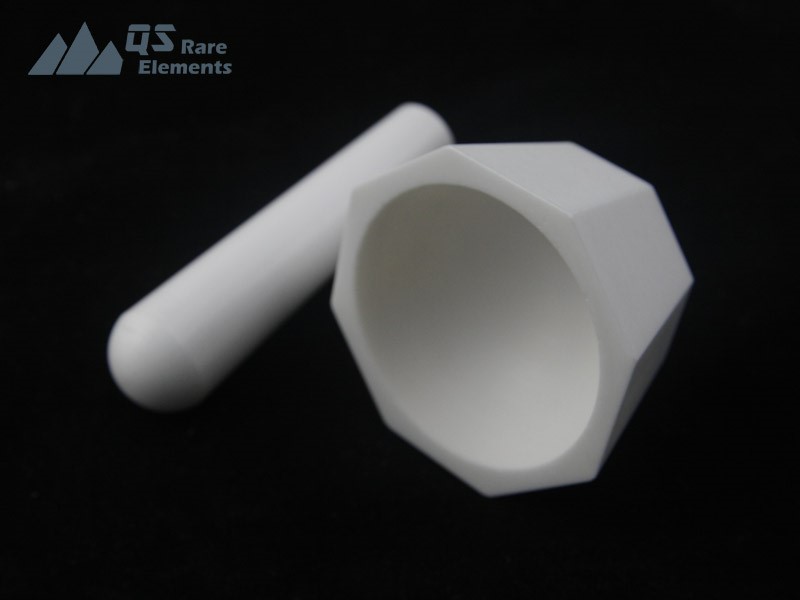

Alumina and zirconia are used in ceramic manufacturing. But the two differ in the way the end product is seen. Alumina has a much higher density than zirconia. The zirconia stabilize yttria also has very good corrosion resistance. Zirconia stabilized is a more suitable material for the manufacture of mechanical components. Its materials are the most durable materials for mechanical parts and ceramic parts. Ceramic made with zirconia stabilized is widely used to deal with corrosive chemicals and molten metal. Due to its high resistance to abrasion and corrosion, it is less contaminated than alumina. Custom made trace elements are professionally made for advanced ceramics, including important zirconia applications. You can find different ceramics in different stores made using these materials.

Applications of zirconia stabilize yttria in ceramics

Major applications of zirconia stabilize yttria in the manufacture of ceramics include:

- Used in grinding ceramic materials, magnetic materials, and organic materials.

- Used in the manufacture of bearings and other mechanical components because of its high resistance to abrasion.

- Used in the manufacture of special parts such as pumps.

Zirconia stabilize yttria in ceramics

Performance of zirconia stabilize yttria ceramic

Its density in ceramics is about 6.05 g / cm 2. The water absorption in such ceramics is about 0.05%. Ceramics made with zirconia stabilize yttria can withstand temperatures up to 1550 ° C. The amount of pressure and hardness that can be applied is 1350 HV. Its compressive strength is about 25,000 MPa and its expansion coefficient against heat is 9.5 to 10 degrees Celsius. Its bending rate has been tested in the laboratory and the result is 950 MPa.